Equipment Manufacturing

Achieving Automation and Labor Savings through Micro-Component Transfer Technology

Combining our expertise in precision machining, equipment development, and mass production, we excel in automating micro-component handling across industries. We transform manual processes into efficient automated systems, helping customers achieve significant labor savings.

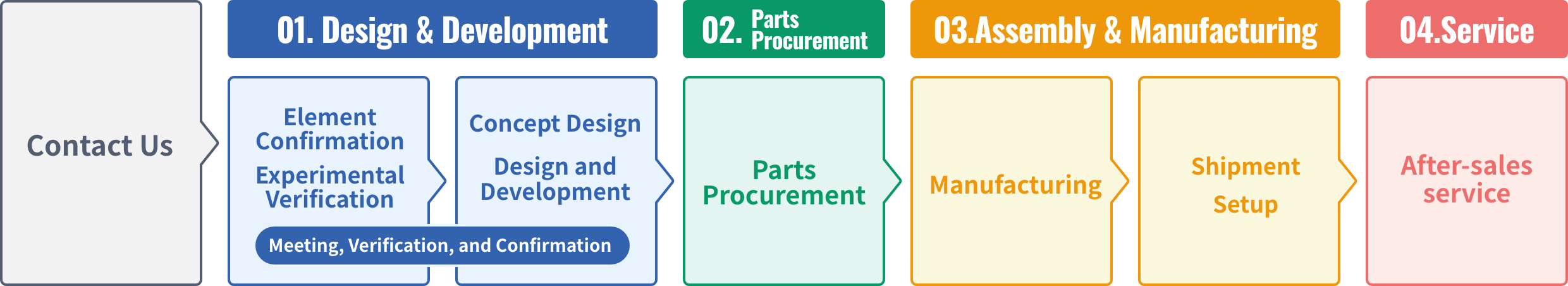

Manufacturing

Integrated Manufacturing Solutions

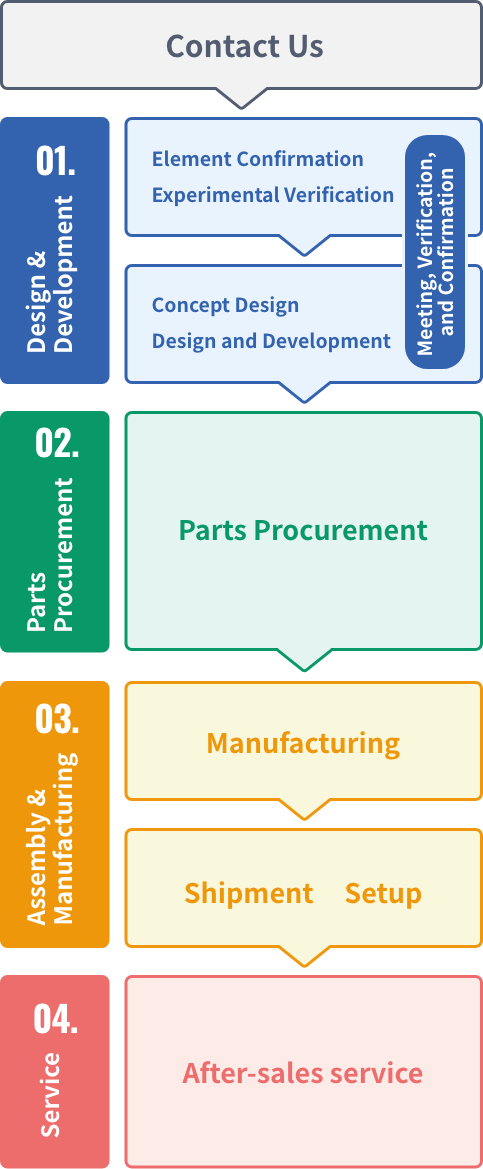

We provide end-to-end support from planning to development, delivering optimal automation solutions through our proven approach to meet customer needs.

We build reliable parts supply networks and procure optimal components based on specifications. We offer competitive pricing and delivery times with diverse options for various parts and materials procurement.

We manufacture customized products based on “MPS” equipment, delivering trusted quality.

We have provided dedicated support for customer challenges over many years, earning satisfaction and trust. Our motto is rapid response to all inquiries.

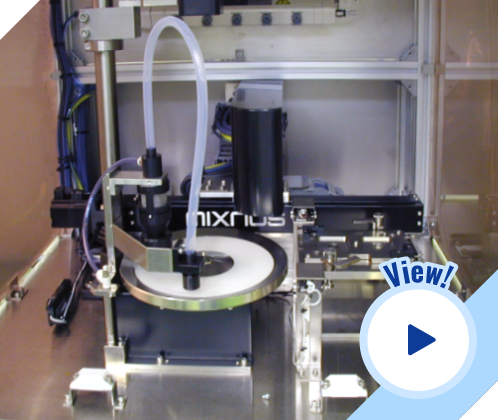

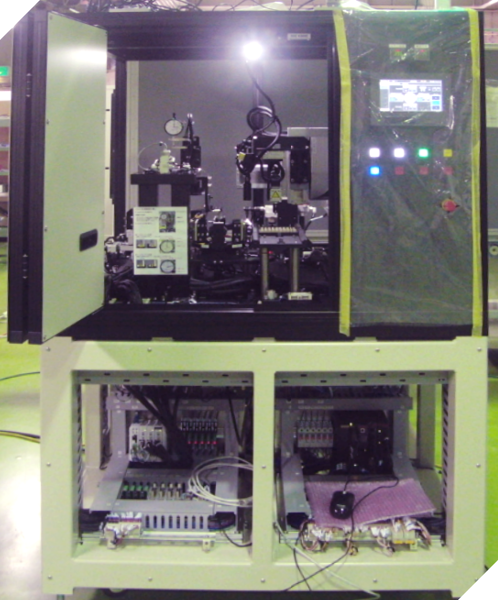

Micro Parts Sorter

Product: Micro Parts Sorter

Micro Parts Sorter

MPS Micro-Component Handling System

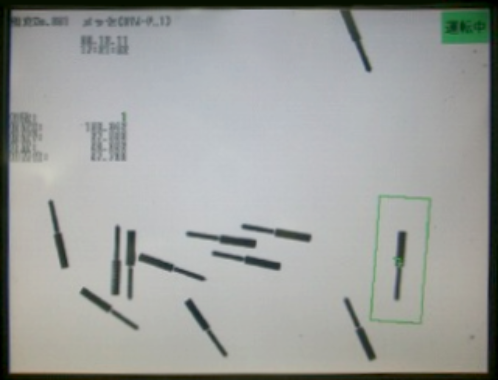

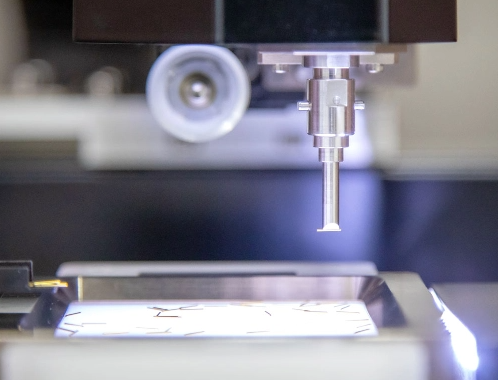

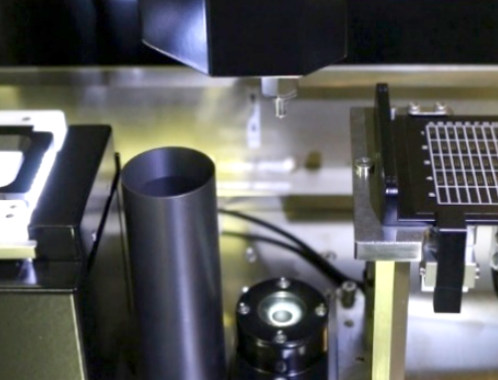

With image processing and a special head, it aligns and picks up ultra-small components that conventional parts feeders cannot handle.

MPS Operation VideoMPS Features

MPS achieves manufacturing process efficiency and quality improvement through high-speed and accurate handling of micro-components using image analysis and special heads. We offer full customization for various parts regardless of material or shape.

Parts Separate

- Complete separation of parts through micro-vibration and rotation

- Minimizing work stress with minimal vibration and rotation

Image Recognition

- Camera captures component outline images

- Dedicated software recognizes shapes, patterns, and angles

Picking

- Reliable picking through vacuum suction with special heads

- Easy product changeover with one-touch head replacement

Alignment

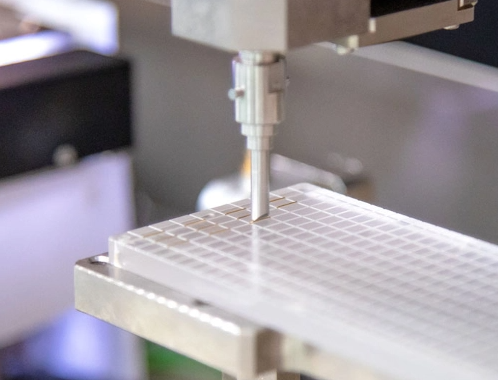

- Precise alignment of micro-components in fixed position and orientation

- Component release without affecting adjacent materials

Additional Camera

- Analysis of enlarged images of post-picking components

- Enables dimensional measurement and shape defect judgment

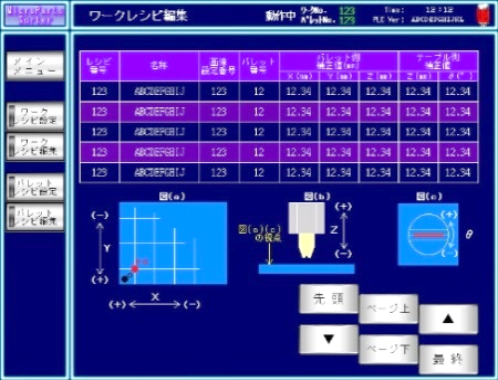

Touch Panel Operation

- Transfer speed, position adjustment, and component type settings through menu and icon tapping

Simple Setup Change

- Can register up to 250 component images

- Setup change for registered products requires only image selection

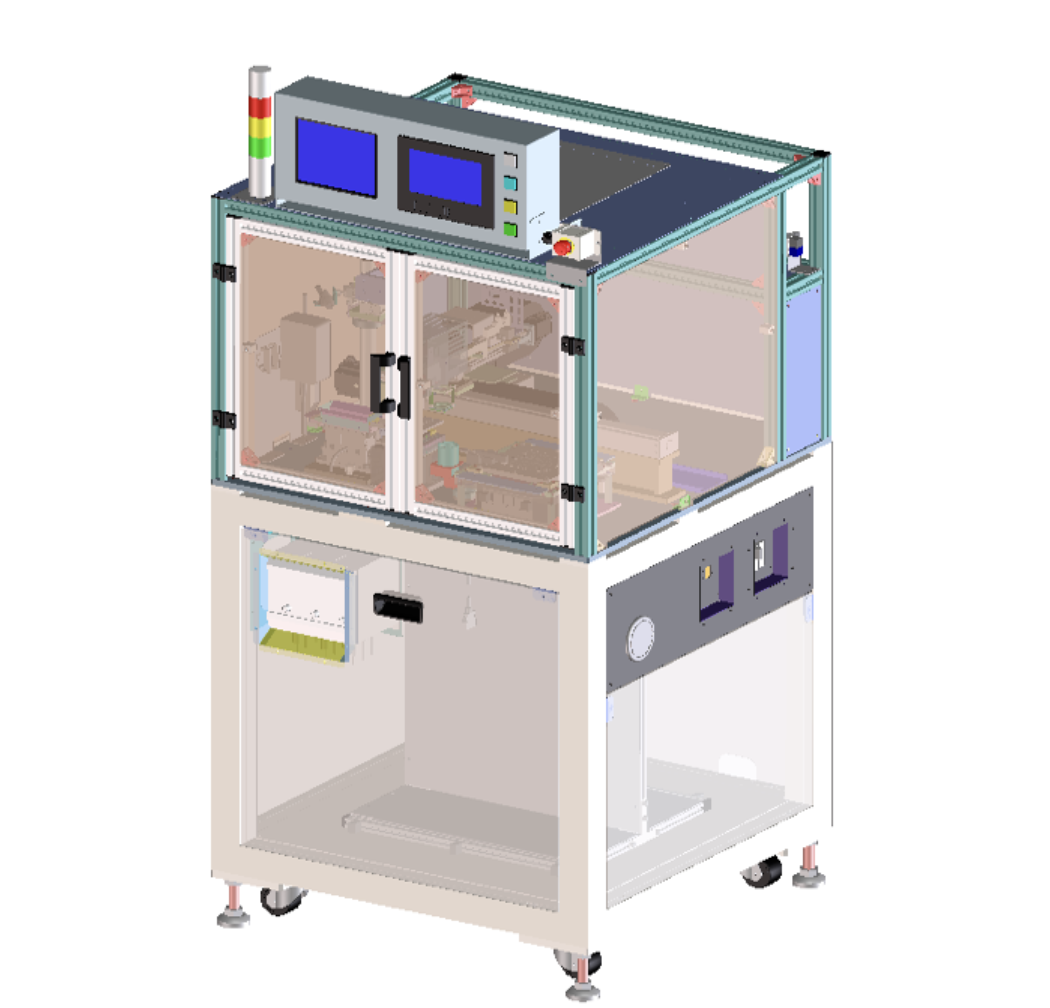

MPS Specifications

Main Unit

External Dimensions

Main Body: Width 800mm × Depth 800mm × Height 1715mm (Reference value)

Equipment Weight: Approx. 400kg (Reference value)

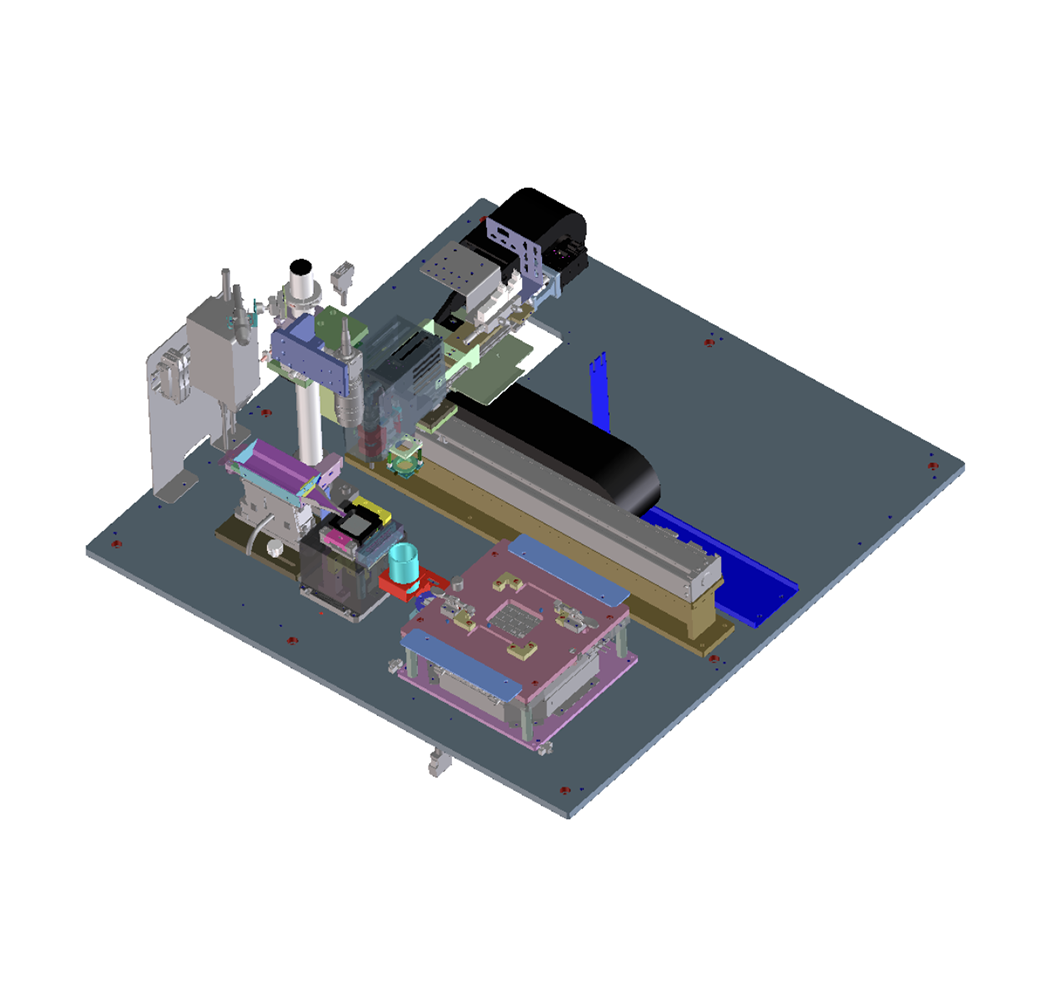

Mechanical Section

Equipment Specifications

(※Dimensions shown are for standard specifications)

| Takt Time | Average 5 seconds/piece (Average alignment cycle time) |

|---|---|

| Loader |

Transfer Method: Vacuum suction Alignment Method: Horizontal lateral alignment |

| X-axis and Y-axis |

Stroke Range: X-axis: 400mm Y-axis: 150mm Repeatability Precision: X-axis: ±10μm Y-axis: ±10μm |

| θ-axis |

Rotation Range: ±180° Resolution: 0.18°/pulse |

| Z-axis |

Stroke Range: ~30mm~ Repeatability Precision: ±20μm |

|

Vibration-type Spread Table (Work Position Confirmation Camera) |

External Dimensions: (W)115mm × (D)100mm × (H)105mm (Reference value) Camera Field of View: □30mm (Varies depending on work conditions) |

|

Rotation-type Spread Table (Work Position Confirmation Camera) |

External Dimensions: φ75-φ170 (Effective area size) Camera Field of View: □40mm (Varies depending on work conditions) |

| Work Orientation Confirmation Camera (Additional Camera) |

Recognition Range: Target work range Camera Field of View: 1.65×2.2[mm] (With 2x lens) |

| Pallet Section |

Specified single type of pallet Dimensions: ~150mm~ × ~150mm~ |

| Suction Head | Work-specific custom head (In-house design) |

| Power Supply: |

Input Power: AC200-220V Single phase ±10% Power consumption: 2kVA or less Connection: Hook-type plug 4222R (American Denki) |

| Pneumatics |

Air Pressure: 0.4MPa to 0.8MPa Air Consumption: 230L/min(MAX) (Depends on ionizer consumption) Connection: φ8 tube fitting |

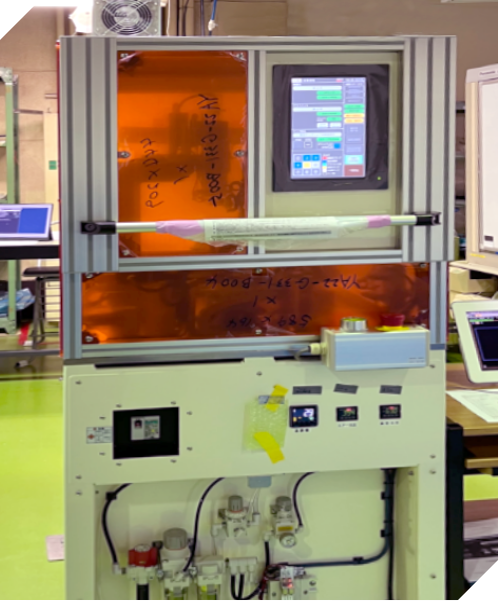

MPS Integration Examples

Optical Device Component Transfer Equipmen

Optical Device Component Transfer Equipmen

Laser Diode Transfer System

Semiconductor-related Parts Transfer System

Exposure Equipment

Automatic Probe Pin Assembly Machine

Other Products

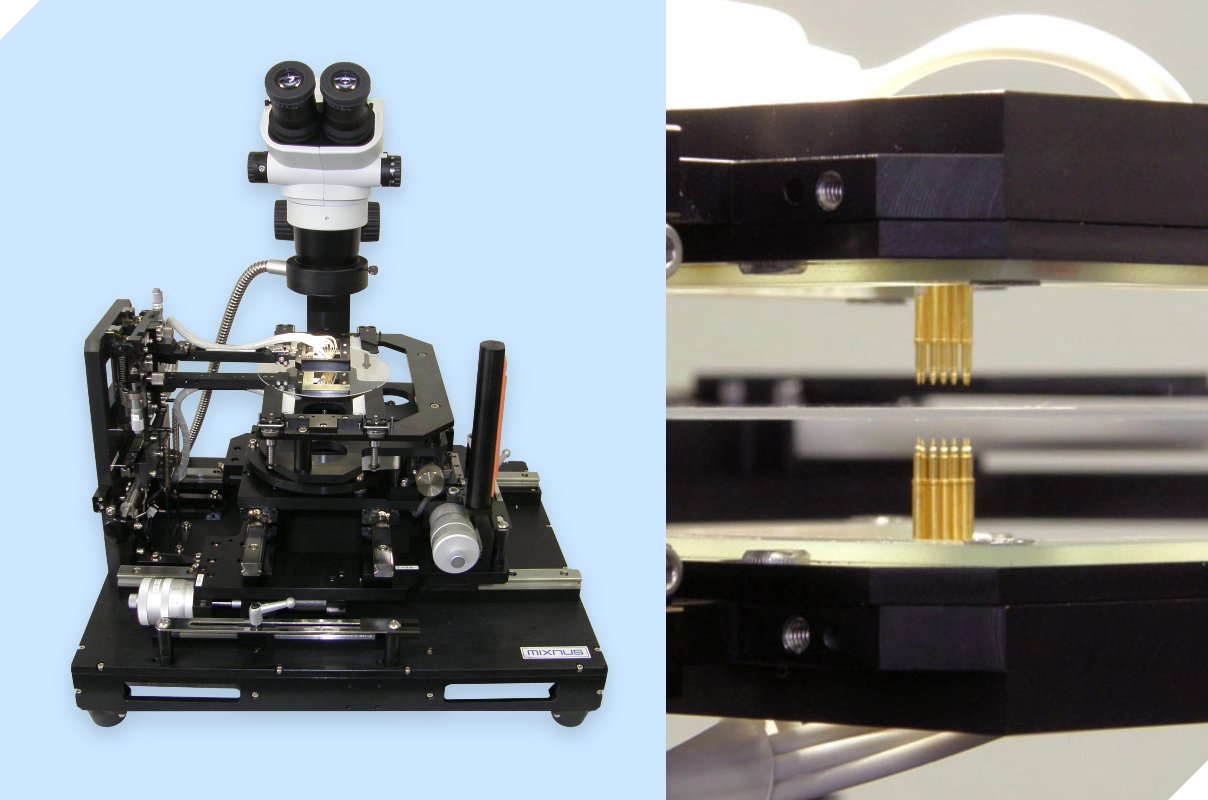

Double-Side Manual Prober

Enables low ON-resistance measurements and high-current measurements of power devices through double-sided wafer probing.

Equipment Specifications

| Applied Voltage/Current | 1500V・DC200VA |

|---|---|

| XY Stage Simultaneous Drive | |

| Stroke | X-axis: 170mm (coarse adjustment) Y-axis: 160mm (coarse adjustment) θ-axis: ±10° |

| Dimensions | Main Body: W550×D455×H643 |

| Weight | 48㎏ |

| Options | 5 Micro-positioners Spring Test Probe Tungsten Needle Probe Card Heater Unit |

Patent obtained (No. 5599341)

Contact

For inquiries about our products, business operations, or employment opportunities, please feel free to contact us.

Contact Form